Is a WMS the holy grail of warehouse operations?

Warehouse management systems (WMS) have been promised as the all encompassing solution for warehouses today. A single source of truth for all of your data so you can make fast and accurate decisions.

Don’t get me wrong, a WMS has its merits, it’s great for things like inventory management and tracking SKU performance — but relying solely on a WMS to run your operations today is a recipe for disaster.

Here are 5 reasons why.

5 reasons why your Warehouse Management System (WMS) isn’t enough to run your operations today

1. Can’t get actionable data in one place

WMS, LMS, TMS, ERP — I’m getting dizzy just thinking about it.

There are so many different systems (and manual data-entry or paper processes) that warehouses use today. Just getting access to that data is already a challenge without IT support.

Then you have to get it all into one place (typically a mountain of spreadsheets, not natively in your WMS).

And then you have to try and analyze that data to make actionable decisions.

See the problem here? By the time you’ve managed to pull reports from 5 different systems, dump them into Excel spreadsheets, create macros and pivot tables to actually make sense of that data… you’re probably too late.

And you just spent hours (or days) of your time that was better spent elsewhere.

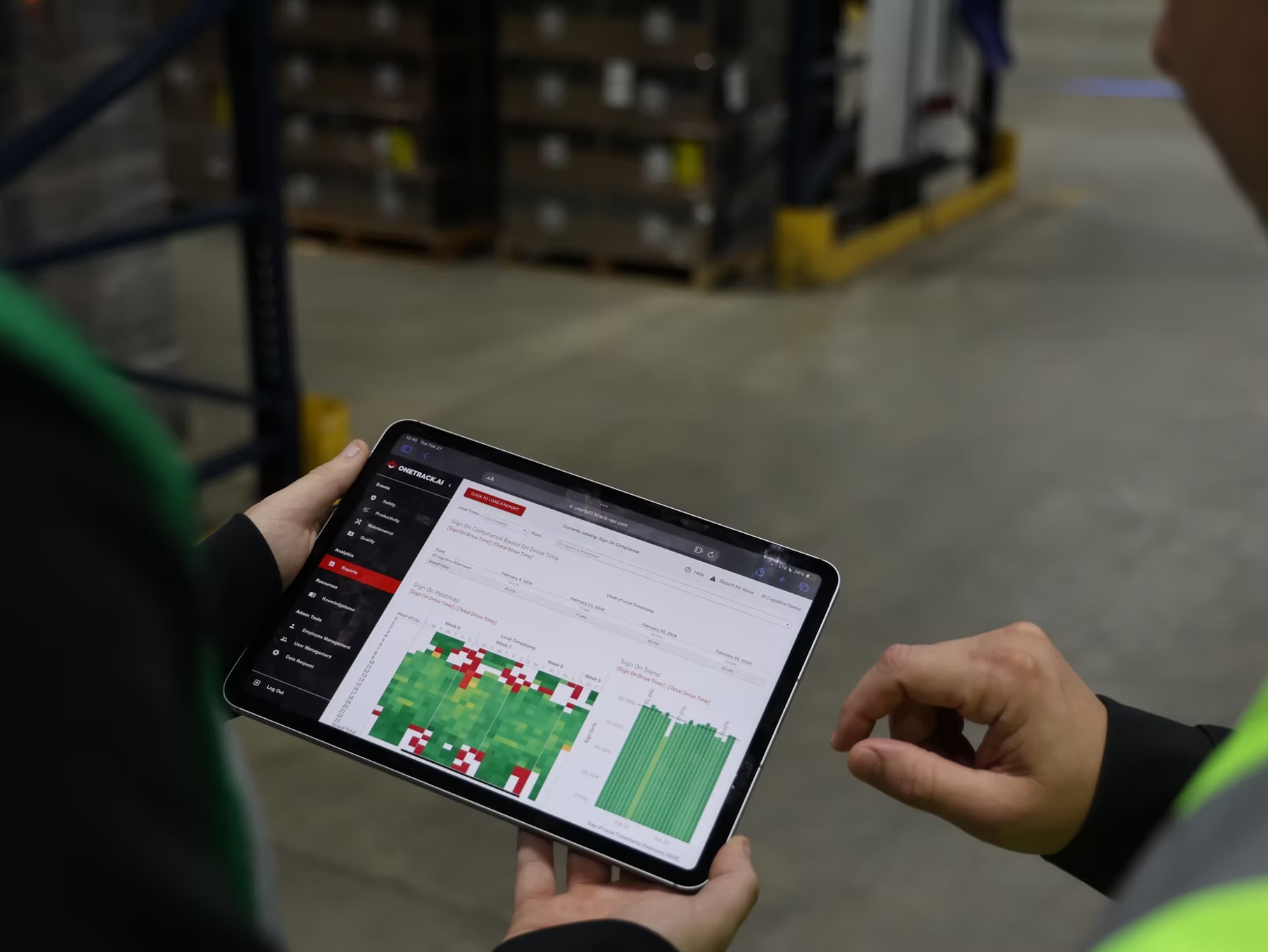

I’m not saying you can ditch spreadsheets altogether. But there are better options out there to integrate all of your key systems together, analyze them in real-time, and give you actionable, timely alerts to make meaningful changes in your operations.

At OneTrack we call this Warehouse Intelligence. Think it sounds too good to be true? Here's what ID Logistics had to say about it.

2. There are too many holes in the visibility a WMS alone gives you

Most warehouse management systems still run on technology invented in 1948. Barcodes.

Barcodes are great tools, and we highly recommend that every warehouse use them, but all they provide is timestamp data (and location data if you have them tied to bin locations).

You know that an employee got a pallet at 10:01am and then that they dropped it off 22 minutes later.

22 minutes? That seems like a long time for a standard pallet move. What happened?

If all you have is a WMS, you’ll never really know.

Was it a wifi issue that caused the data to sync poorly? Was the employee just dragging their feet? Process impediment?

With an AI forklift system like OneTrack, we work with your WMS to show you everything in between. What route they took, how safely they were operating, if they had to move multiple pallets to get to what they needed, if they stopped for 10 minutes to scroll social media.

With that kind of visibility, combined with real-time alerts, you can focus on having high impact coaching conversations with operators, improving your processes that lead to the most bottlenecks, and ultimately skyrocketing your gross margins.

3. Warehouse management systems are complex, bulky, and slow to change

Ever heard the analogy “It’s a big ship. It takes a lot of time to change directions”? I’m pretty sure whoever said this was talking about a warehouse management system.

The average WMS implementation takes 6-8 months on average. That’s a long time to wait to get any ROI from a system you just paid a lot of money for.

In comparison, with OneTrack you’re only looking at 4-6 weeks to get up and running and 6-12 months to achieve a positive ROI.

Warehouse management systems are notorious for being bulky, complex, and incredibly difficult to customize without shelling out money for a consultant or bringing in dedicated IT resources.

Not every logistics company can afford that kind of investment (of time and money). Oftentimes you’re left with a good product, but not a great one.

Warehouses move fast and your technology shouldn’t just keep up. It should get you ahead. Otherwise you’re stuck playing defense, putting out fires, instead of making your data work for you.

By combining your WMS with a system like OneTrack, you can start playing offense with your operations.

4. WMS’ struggle to go from historical to predictive

You need to shift your operations from playing defense to playing offense.

The only way you can do that is with data that isn’t just historical (how we did) but data that's predictive (how we can do it better).

WMS’ struggle here. They’re better rearview mirrors than they are windows into the future.

Sure, you can see volume from last year and project things out manually, but we all know that the warehouse world is all about fluctuating demand, labor pressures, cost challenges, and more.

AI is the only way to truly become predictive with your data. This means finding potential bottlenecks before they ever slow things down. Or allocating labor more effectively to handle fluctuations in demand.

Or maybe it’s simply finding leading indicators of safety incidents and key drivers of productivity losses so you can coach operators before the major accident ever happens.

5. Customers’ are demanding more data than a WMS can provide alone

Last on the list might be the biggest reason in the near-term why a WMS alone isn't enough to run your operations — at least for 3PLs.

The status quo has changed in the relationship between 3PLs and their shipper/manufacturer customers. In the past a historical performance report may have been fine but not anymore.

At OneTrack, we’re seeing more and more shippers, brands, and manufacturers proactively seek us out for real-time operational data.

They want to know what’s happening with their goods at all times. They want to know how safely your operators are performing. They want to know your plan to optimize labor costs while keeping quality high.

There's a massive opportunity out there for 3PLs to use technology, in conjunction with their WMS, to position themselves as a true partner instead of just a vendor.

But it all comes down to accessible, actionable, and predictive data. That’s what customers are after.

Would rather be caught on the back foot or proactively get ahead of these expectations?

OneTrack + WMS = Warehouse Intelligence built for modern logistics

Your WMS is a great tool. But it’s not the whole toolkit.

The best logistics leaders recognize this and find systems that can work with their WMS to create true Warehouse Intelligence.

OneTrack works with hundreds of warehouses across North America to do just that. Pull in data from your key warehouse systems, use AI to analyze operations in real-time, and then provide deep visibility into your safety, productivity, and quality so you can make meaningful improvements.

Get a demo to see it in action today. Or do your research first and check out how Hain Celestial is using OneTrack to upgrade their operations.