AI Cameras and Sensors Built for Warehouses

Connect your physical operations to digital intelligence.

Connect your physical operations to digital intelligence.

Purpose-built cameras capture the data your operations need—from overhead views on equipment to strategic fixed positions throughout your facility.

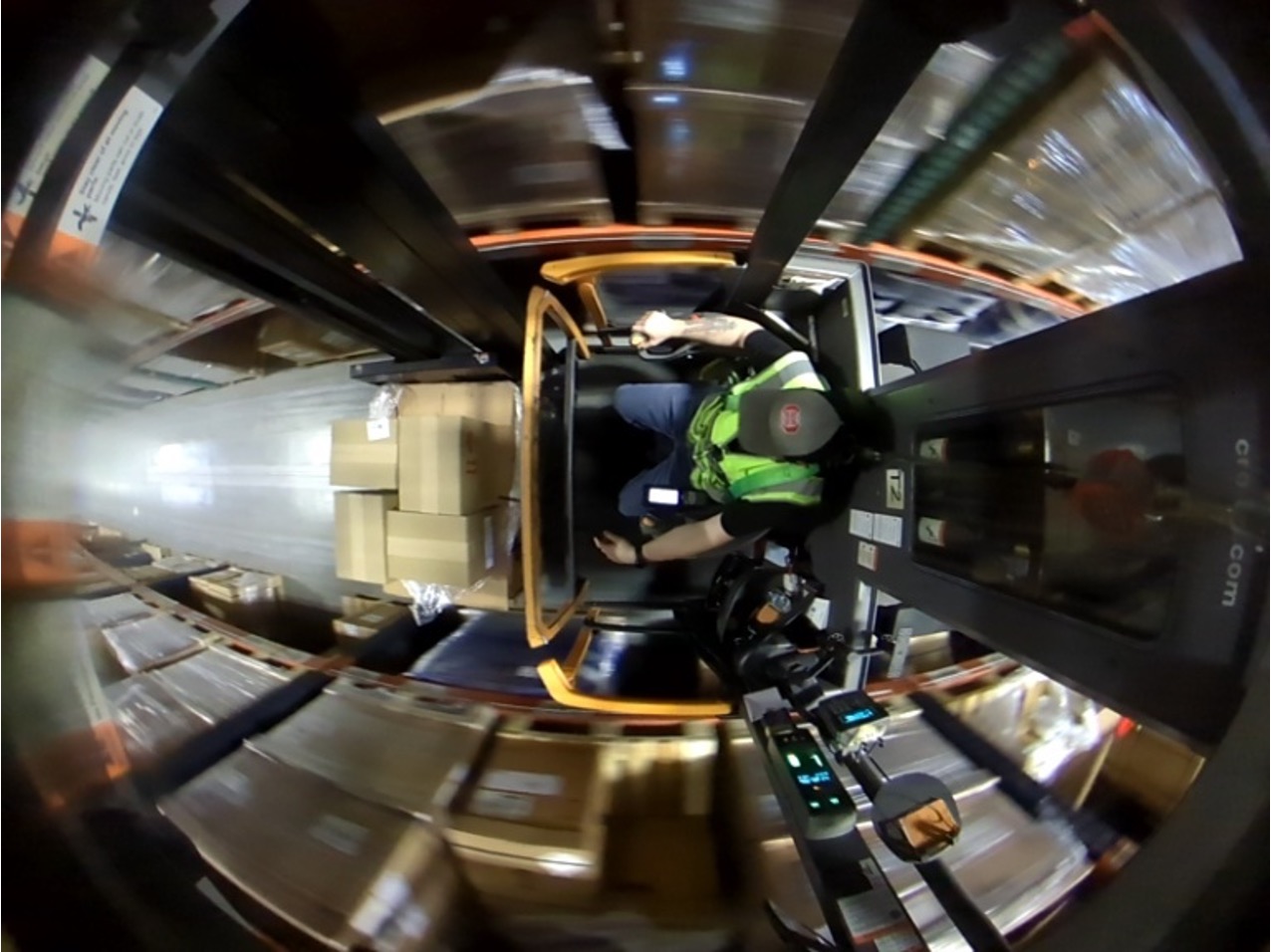

360° views from mobile equipment capture operator behavior, surroundings, and interactions

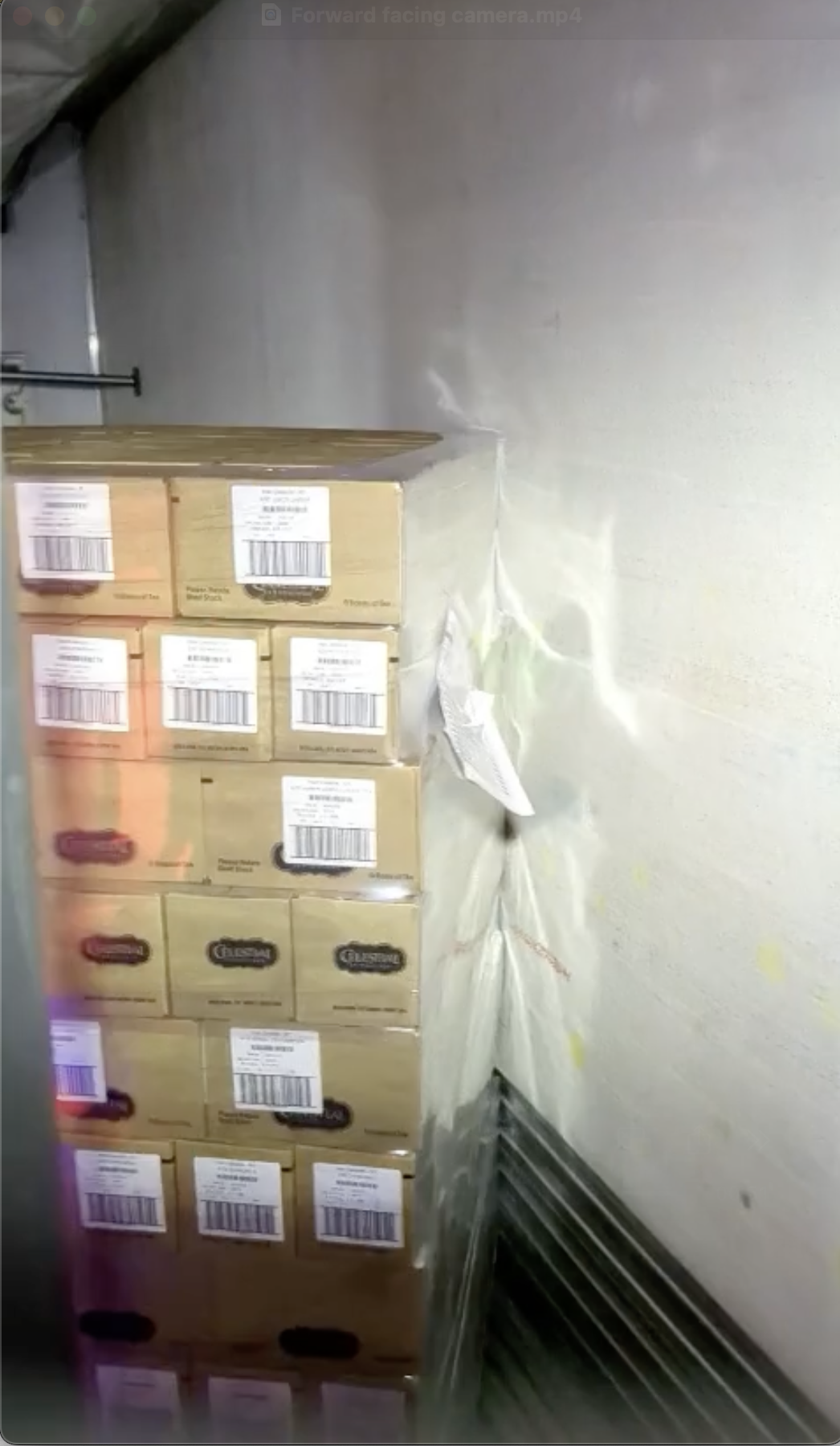

Equipment-mounted views capture what operators see ahead

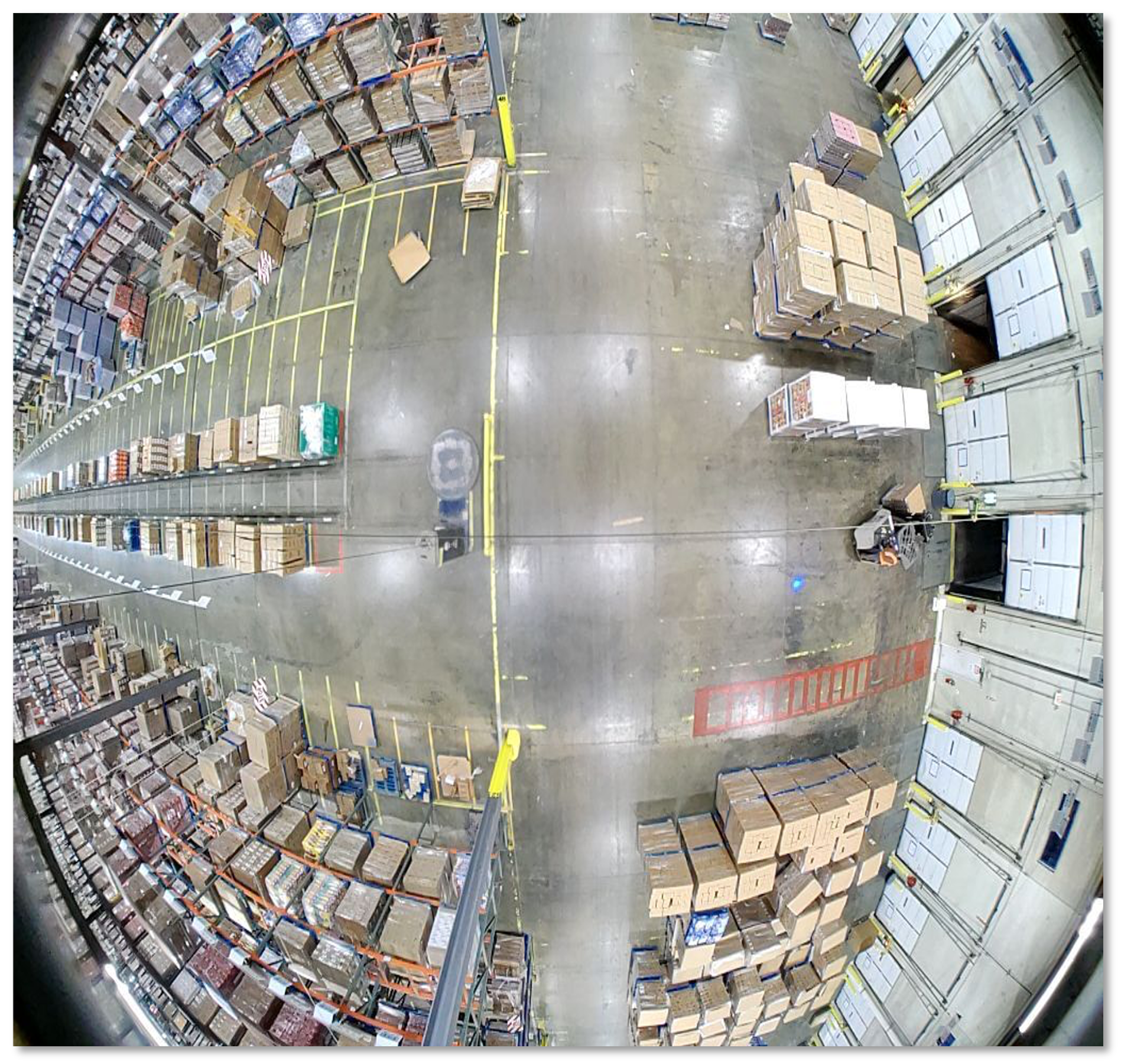

Fixed positions capture workflow, quality, and facility-wide activity

Purpose-built AI models trained on millions of hours of warehouse footage to identify safety risks, productivity issues, and quality problems in real time.

Detect physical conditions that cameras miss and get alerted about issues before they become problems.

Monitor cold chain compliance, detect HVAC failures, and get alerts when thresholds are exceeded.

Detect when equipment approaches people, objects, or restricted zones. Enable collision avoidance alerts.

Track battery voltage, door open/close states, and equipment on/off status for full operational awareness.

Detect impacts, unusual vibrations, and movement patterns to identify equipment issues early.

No IT projects. No network changes. No infrastructure overhaul.

Schedule a demo to learn more about deployment and understand how OneTrack fits your operation.