“Logistics companies need to view technology as a competitive advantage, because the ones that do won’t just get by, but will actually use it as a competitive advantage.”

Technology can be a game-changer for logistics companies. But in a world of razor thin margins, constant firefighting, and labor challenges (to put it lightly) — it’s not always an easy jump to make.

The logistics leaders that make the investment now will stand out in a crowded market, increase margins, and solve some of the biggest challenges facing logistics companies today.

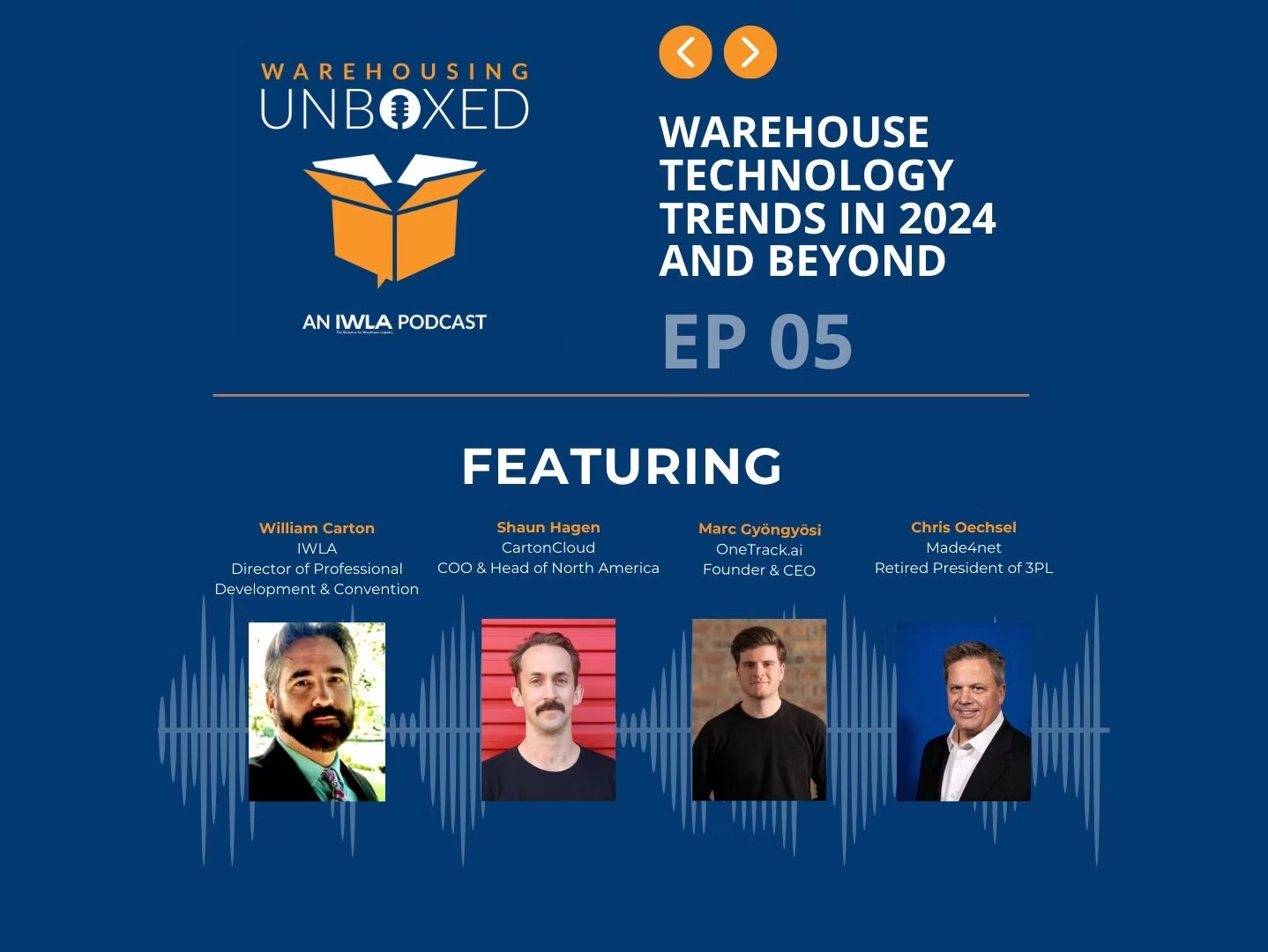

And this podcast, hosted by IWLA, talks about exactly how to do it.

Watch the full podcast here or read on for the key takeaways.

3 Key Takeaways for Logistics Leaders:

Takeaway #1: The current status quo in logistics is… challenging

Whether you’re in a 1.5 million square foot warehouse with 150 forklifts or a 50,000 square foot building with 3 forklifts running — the challenge is the same.

A lack of visibility that makes improving safety, productivity, and quality in your operations really challenging.

Most warehouses today run on technology from the 1940’s and 50’s: the barcode. And while barcodes are great for timestamps, they don’t give logistics leaders visibility into why something happened.

And without that visibility, it’s almost impossible to make real change. Technologies like AI bring that level of visibility you need.

Takeaway #2: Customers want more access to data than ever before

Every panelist brought up the same thing: 3PLs' customers are demanding more visibility and access to data than ever before.

The days of operating “behind closed doors” are gone. Customers crave visibility into your strategies, improvement plans, and data.

The 3PLs who adopt this mindset now, have a huge opportunity to position themselves as valuable partners for their customers.

It starts with finding ways to make your data both accessible AND actionable (we’ll cover that next), and communicating with customers before any problems arise.

That kind of proactive collaboration is how 3PLs can stand out in a crowded market today.

Takeaway #3: AI is making data actionable not just accessible

Everyone can agree that warehouses have access to a lot of data.

The challenge has always been around unlocking that data and using it in an actionable way.

Warehouses have to deal with multiple systems and paper processes— which has historically made getting that data into one place a huge challenge.

Not only that, but even if you are able to get data into a centralized place, most employees aren’t data scientists.

AI systems — like OneTrack — have unlocked the ability to integrate all of your major systems into one place, use AI to do the heavy lifting, and start making actionable decisions immediately.

The combo of legacy data, video evidence, and AI analysis is what will take operations to the next level.

Considering bringing AI into your operations? Safety can be low hanging fruit for major improvement. Check out this guide to building out an AI forklift safety program.