The enterprise stack for physical operations is broken.

Not in the way a server goes down or a bug crashes an application. Broken in a more fundamental way. The software running warehouses, factories, and distribution centers was designed in the 1990s. It captures transactions, not reality. It records what should happen, not what actually does.

This matters because physical operations represent 30% of global GDP. A $28 trillion sector. Everything you buy has to be made somewhere, stored somewhere, moved multiple times before it reaches you. And all of it runs on architectures that predate the smartphone.

While digital businesses transformed with AI, physical operations got left behind.

That's changing now. The convergence of computer vision, AI agents, and cloud infrastructure is enabling something new: the warehouse operating system. Not another point solution. Not another module to add to your existing stack. An entirely new layer that sits above everything else, capturing ground truth and acting on it autonomously.

The Fragmented Enterprise Stack

Walk into any modern warehouse operation and you'll find a patchwork of disconnected systems.

WMS (Warehouse Management System) knows where inventory should be. It tracks putaways, picks, and shipments. But it has no idea what actually happens between scans.

ERP (Enterprise Resource Planning) provides a financial view of operations. Costs, revenues, inventory valuations. Completely disconnected from the floor.

LMS (Labor Management System) measures outcomes. Units per hour. Tasks completed. But it can't tell you why performance is high or low.

TMS (Transportation Management System) manages shipments, carriers, and routes. It has no visibility into loading quality or dock operations.

YMS (Yard Management System) tracks trailers and dock appointments. It can't see what drivers or operators are actually doing.

HRIS (Human Resource Information System) stores employee records, certifications, and training history. Zero operational context.

None of these systems talk to each other. Each has a partial view. None has the truth.

Consider a simple scenario: Your WMS shows an operator scanned a pallet at 10:00 AM. The same operator scanned it again at 10:15 AM. But what happened in those 15 minutes?

Was there a safety near-miss? Did equipment malfunction? Was the operator helping another associate? Did a process breakdown cause delay? Did they take a 15-minute phone call?

Nobody knows.

The enterprise stack captures timestamps, not reality. It records what was typed into systems, not what happened on the floor. And when you don't know what actually happens, you can't make intelligent decisions. You can't coach effectively. You can't identify root causes. You can't improve.

The Visibility Gap

The fundamental problem is that existing systems were designed to be systems of record. They store data that humans or other systems provide to them. They trust that data is accurate.

But in physical operations, that trust is misplaced.

Manual entry introduces errors. Timestamps capture events without context. Siloed systems create conflicting records. Delayed updates mean decisions based on stale information. Supervisors can observe maybe 5% of what happens on their shift. The other 95% is invisible.

This visibility gap has real consequences.

Safety incidents happen with no evidence of what led up to them. Productivity problems persist because no one can identify root causes. Quality claims become disputes because there's no proof of what actually occurred. Every absorbed cost erodes margin.

The legacy systems aren't going away. The WMS market alone is valued at $8.6 billion. Enterprises have invested billions in these systems. They're not going to rip and replace them.

But they can add something above them. An intelligence layer that captures what's actually happening and makes sense of it.

What a Warehouse Operating System Actually Is

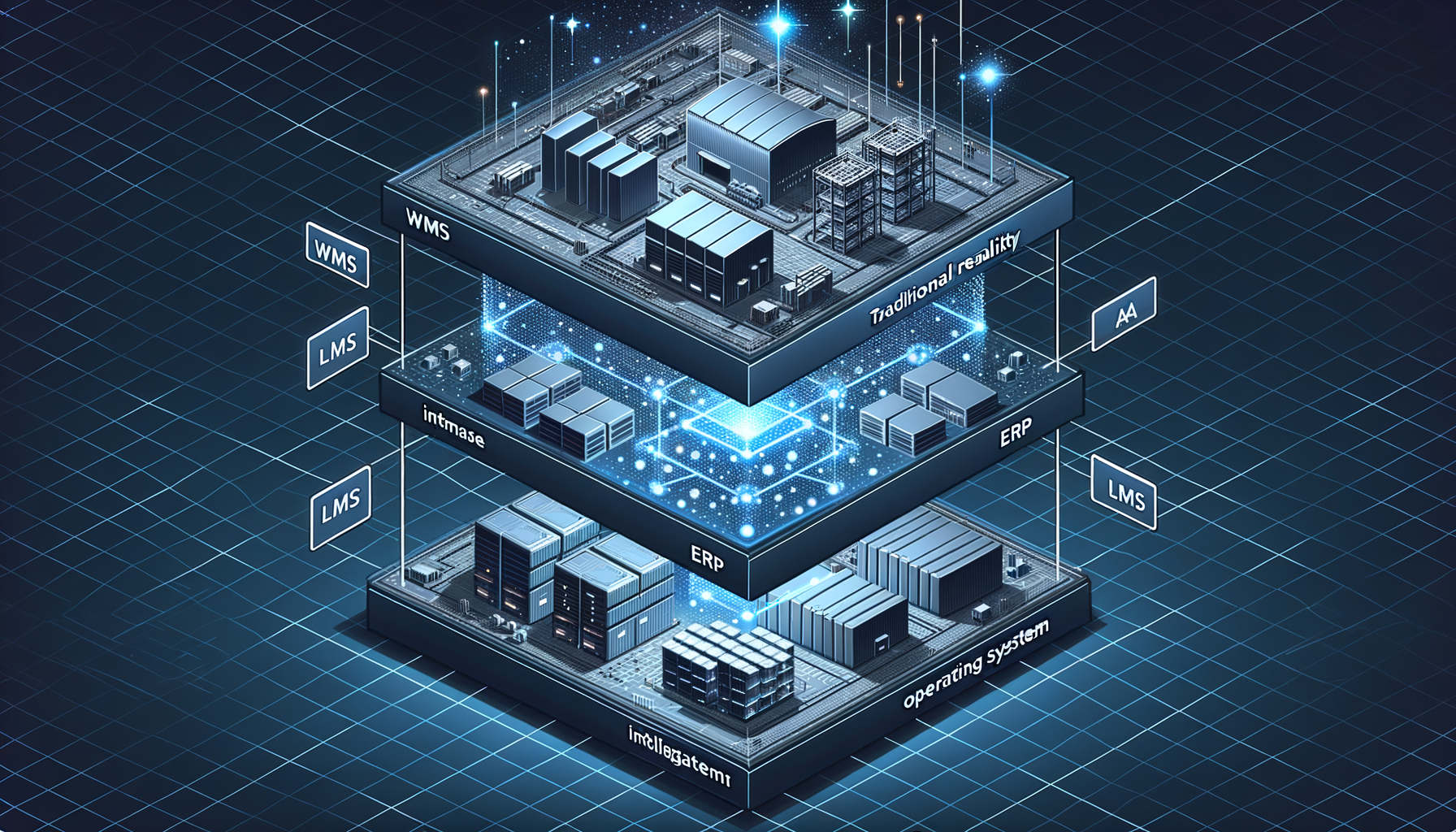

A warehouse operating system is the layer that sits above your existing infrastructure. It doesn't replace your WMS, ERP, or LMS. It connects them. And more importantly, it adds what they've always been missing: ground truth.

The architecture has three layers.

Layer 1: CAPTURE

Sensors become the foundation. Not just any sensors. Cameras.

Cameras are the most powerful sensors in the world. Every other sensor gives you a single data point. A temperature reading. A G-force measurement. A location ping. A camera captures everything: context, sequence, cause and effect.

The problem was never capturing video. A single forklift generates 8+ hours of footage per shift. Multiply by 50 forklifts, 3 shifts, 7 days a week. That's over 8,000 hours of video per week from forklifts alone. Add dock cameras, zone cameras, workstation cameras. No human can watch that.

Computer vision solves this. Neural processing units enable real-time visual intelligence at the edge. Identifying, classifying, and tracking instantly. Not storing everything and reviewing later. Processing in the moment and surfacing only what matters.

The result is continuous ground truth across every operation, every shift, every site. You finally know what actually happened.

Layer 2: UNDERSTAND

Raw data isn't insight. The second layer filters, analyzes, and contextualizes.

What happened that was exceptional? What patterns are emerging? What requires human attention?

This is exception-based operations. Surfacing the 2% that needs attention, not the 98% that's fine. A supervisor doesn't need to know that 47 out of 50 operators are performing well. They need to know which 3 need help and why.

The power comes from combining sensor data with system data. When you connect video with WMS transactions, LMS metrics, clock punch data, and equipment telemetry, AI can answer questions that were previously impossible.

Why is this operator underperforming? Show me the video.

Where did this damage occur? Trace the product journey with footage at every touchpoint.

What behaviors precede safety incidents? Analyze thousands of events to find the pattern.

This layer transforms raw visibility into operational intelligence. Not more dashboards to check. Answers delivered when they're needed.

Layer 3: AUTOMATE

The final layer is AI agents that take action.

Not chatbots. Autonomous digital workers with access to your systems and the ability to act within defined guardrails.

Traditional approach: Dashboard shows a problem. Manager pulls a report. Investigation takes hours. Coaching requires preparation. Action happens days later, if at all.

Agentic approach: Agent identifies the problem. Investigates automatically. Assembles evidence. Generates coaching plan. Delivers it to the supervisor. Tracks follow-up.

This is the work of 100 engineers with a single person. Reports generated automatically. Investigations completed in minutes instead of hours. Coaching plans created without prep time. Exceptions surfaced and prioritized before anyone asks.

The three layers work together. Sensors capture reality. AI extracts intelligence. Agents act on it. Humans handle the exceptions that require judgment.

Why This Is Different From WMS

A warehouse management system tells you where inventory should be. A warehouse operating system tells you what's actually happening with your people, processes, and products.

WMS is a system of record. It stores what you tell it. Warehouse operating system is a system of reality. It captures what occurs.

The relationship isn't competitive. It's complementary.

The warehouse operating system sits above WMS, pulling transaction data and enriching it with visual context. When your WMS says a pick happened at 10:15 AM, the warehouse operating system shows you the video of that pick. When your LMS says an operator completed 45 units per hour, the warehouse operating system shows you where the other 10 units went.

Integration is one-way. Data flows from your existing systems into the intelligence layer. You don't have to modify your WMS. You don't need a massive IT project. The warehouse operating system adapts to your infrastructure, not the other way around.

This matters because the enterprises that need this most are the ones with the most complex legacy environments. They run SAP, Blue Yonder, Manhattan, HighJump, and homegrown AS400 systems. Sometimes all at once across different facilities. A new intelligence layer has to work with all of them.

What Becomes Possible With Ground Truth

When you actually know what happens in your operation, everything changes.

Safety transforms from reactive to predictive. Instead of investigating incidents after they happen, you identify the behaviors that precede them. Phone use while driving. Speeding through intersections. Failing to stop at stop signs. These leading indicators surface before someone gets hurt. You coach on behaviors, not accidents.

Productivity becomes coachable. When an operator underperforms, you don't just tell them to work faster. You show them the video. You identify the specific behavior causing the gap. Extended breaks. Excessive travel time. Inefficient pick paths. The conversation shifts from accusation to observation.

Quality claims become provable. When a customer claims a shipment arrived damaged, you have the footage. Every load, every touchpoint, every transfer. The debate ends. Either the damage happened in your facility or it didn't. You have proof either way.

Labor management becomes real. Traditional LMS measures outcomes without context. It tells you someone completed 45 picks per hour without telling you they spent 20 minutes on an unscheduled break. With ground truth, you see gap time, idle time, indirect time. You understand where productivity actually goes.

Continuous improvement becomes possible. Engineering teams spend weeks doing time studies, creating spaghetti diagrams, analyzing workflows. With a warehouse operating system, that data exists continuously. Travel patterns. Dwell times. Bottlenecks. All visible, all the time, without sending an engineer with a clipboard.

The Transformation Roadmap

Moving to a warehouse operating system isn't a multi-year IT transformation. It happens in phases, each delivering value.

Phase 1: Visibility (Weeks)

Deploy sensors and establish ground truth. The immediate impact is simple: you can finally see what happens on night shift. You can investigate quality claims with video. You can answer questions that were previously impossible.

Most operations start here because they literally cannot answer basic questions about their own facilities. What happened at Dock 7 last Thursday? Why did that load arrive damaged? Where is productivity being lost?

Sensor deployment takes weeks, not months. Self-contained units with built-in connectivity. No IT project required.

Phase 2: Intelligence (3-6 Months)

With ground truth established, pattern recognition begins. Which behaviors precede accidents? What process breakdowns cause delays? Where are the hidden inefficiencies?

This phase transforms reactive organizations into proactive ones. Instead of responding to incidents, you prevent them. Instead of explaining productivity dips after the month closes, you address them in real time.

The intelligence layer integrates with your existing systems. WMS, LMS, HRIS, timekeeping. Data flows in, context flows out.

Phase 3: Automation (6-12 Months)

With visibility and intelligence in place, automation becomes possible. Coaching plans generated automatically. Claims investigated without human intervention. Reports delivered proactively. Exceptions surfaced and prioritized.

Human workers shift from routine tasks to exception handling. Supervisors stop pulling reports and start acting on insights. Managers stop investigating and start deciding.

This is where AI agents take over the work that used to require people. Not the physical work. The cognitive work. The analysis, the investigation, the report generation, the follow-up.

Phase 4: Optimization (12+ Months)

With agents handling the routine, humans focus on strategic improvement. Labor planning informed by actual utilization data. Fleet sizing based on real usage patterns. Layout optimization driven by actual travel paths.

The facility continuously analyzes its own performance, identifies improvement opportunities, and implements changes. Human oversight remains. Human initiation becomes optional.

The Choice

Physical operations stand at an inflection point.

The technology is ready. Computer vision accuracy exceeds 98%. AI agents can reason about complex situations. Edge computing enables real-time intelligence. The economics work at scale.

The pressure is real. Labor costs keep rising. Turnover remains stubbornly high. Margins compress. Customers demand more visibility. "Trust me" doesn't work anymore. Proof is required.

The early movers are building advantages that compound over time. More data trains better models. Optimized operations are hard to replicate. Workers prefer modern environments. Visibility and proof win contracts.

The question isn't whether this transformation will happen. It's whether you'll lead it or follow it.

The enterprise stack for physical operations is being rebuilt. The warehouse operating system is the intelligence layer at the center of it. Sensors capture reality. AI understands it. Agents act on it.

The companies that get there first will define what operational excellence looks like for the next decade.

The window is open now.

Related Articles

- What is Agentic AI? - The AI agents that power the operating system

- Real-Time Warehouse Intelligence - From dashboards to action

- Computer Vision for Warehouses - The CAPTURE layer explained

- AI Agents for Warehouse Operations - The AUTOMATE layer in detail